|

"“Everything is integrated now. We have the shop floor data capture and document management included, so everything is on one system. We’ve improved efficiency of production engineering processes by 40%, and have now generated new saleable capacity, without increasing our costs.” Lyndhurst Precision

|

One MRP System For Your Manufacturing Business

|

As your business grows, you gain new customers, new suppliers and more staff to manage. Stringent regulations and new customer specifications can put increasing pressures on your business to reduce prices but improve delivery and customer service levels.

To adapt among the mounting paperwork and compliance requirements in your production process, you need to reduce inefficiencies and streamline operations by managing your whole manufacturing process from one integrated system. Tricorn: EnterpriseTricorn: Enterprise is an MRP system developed for for Manufacturing SMEs. It is ideal for companies looking to replace an initial system, or who require better control of production and processes.

|

|

Features |

Sales Engineering

Bring all sales engineering information together in one place. This enables you to automate quotation generation with live accurate information, and tack quotes through to conversion to drive sales initiatives.

Features:

- RFQ Processing

- Estimating

- Quotation Generation

- Win/Loss Analysis

- BOMs

What it means to your business

- Streamline paperwork to quickly turn prospects into sales.

- Easily log, complete and send your quotes. Track their conversion rates and use them as a starting point for entering incoming sales orders.

- With up-to-date and accurate RFQs, you can improve customer communication and confidence.

- Materials are planned at an operation level, ensuring availability of the correct resources at the correct time.

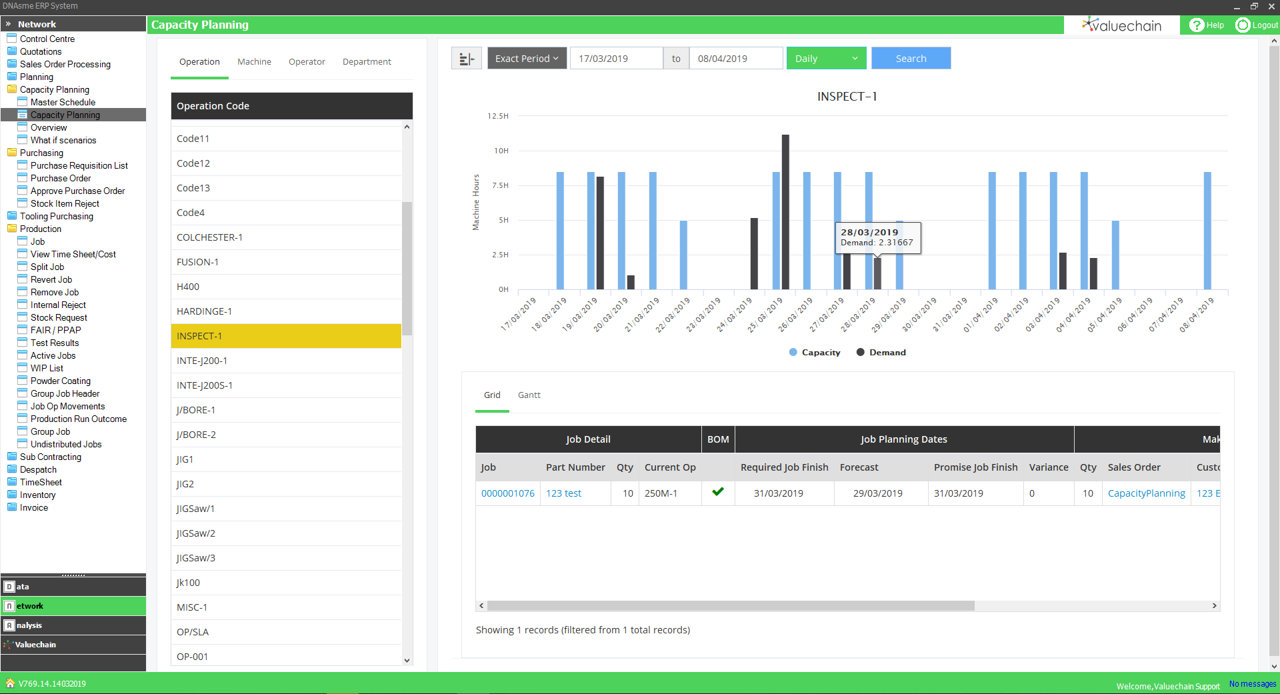

Production Planning

Gain a detailed view of production plans with Tricorn Enterprise. You can allocate machines, operators and resources to jobs in advance, so you can monitor and analyse capacity availability.

Tricorn: Enterprise's visual capacity planning helps to identify bottlenecks in production and improve job visibility to improve the flow of work through the factory.

Features:

- Capacity management

- Scheduling

- Labour, material & tooling planning

What it means to your business

- Analyse current capacity availability using SFDC and jobs-in-production data, to view resources committed and available.

- Provide customers with realistic promise dates that are informed by current capacity availability to ensure you can deliver on-time in full.

“Our whole process is much better managed now, we are able to identify risks, and produce accurate job costings before we even start production.”

- Lyndhurst Precision

Purchasing Control

Purchasing in Tricorn: Enterprise provides central purchase requisition list, which ensures all materials are flagged to be ordered and delivered in time for the appropriate operation whilst controlling stock levels and maintaining traceability.

Features:

- Purchase requisition list

- Create & manage purchase orders

- Inventory management

- Goods-in stores

- Paint & chemicals

What it means to your business

- Easily produce purchase orders, GIN labels and delivery notes to track what’s coming in and going out

- Control Inventory by expiry dates

Quality

Tricorn: Enterprise can remove the need for disparate quality systems and centralise all your quality needs. It allows you to concentrate on continuous improvement programmes whilst ensuring you comply with ISO, IATF & customer requirements.

Log NCRs & internal rejects, and perform full reject analysis to identify root causes and continuously improve performance.

Features:

- Calibration tracking

- Approved supplier register

- Automated SC21 metrics

- Non-conformance management

- Root cause analysis

- Tooling Control

- Inspection

- Certificate of conformity generation

What it means to your business:

- Control all your internal, customer and supplier rejects within one solution; to remove the need for disparate systems and data duplication

- Provide complete traceability for ISO9001 compliance and customer satisfaction

- Manage supply compliance to ensure your supply chain is up to scratch

- All-inclusion tooling control functionality; allowing you to assign specific tools to specific jobs, track tool usage and record calibration history

Finance

Tricorn: Enterprise connects your production information with your financial systems, so you can monitor everything in one place, and easily transfer data without duplication and see how new sales directly impact on financial decisions.

The detailed job costings allow you to see the time & resources allocated to each operation. Utilising Shop floor data collection, Tricorn: Enterprise provides full visibility of the true cost of your processes and a clear understand of each job’s profit margins.

Features

- Auto-generated invoices

- Financial systems integration

- Automated sales & purchase ledge

- Customer & supplier credit management

- Costed BOMs

- Two-way dynamic link with accounting packages, including SAGE, Pegasus and Xero

What it means to your business

- Ensure customers are invoiced accurately & promptly to maximise cashflow

- The live-link with accounting packages allows you to see and act upon real-time credit statuses of your customers and suppliers.

- Put a stop on jobs commencing or deliveries being despatched to customers who have reached their credit limit, reducing the financial risk to your business

- Maintain accurate view of costs from suppliers with Costed BOMs

Integrates with:

SAGE - Pegasus – Xero

“We now analyse our processes in ‘real-time’, enabling us to make more timely and accurate decisions. For example, the dynamic job costing ensures we’re aware of the costs at all times, which enables us to identify the profit from jobs, before we accept them.”

Lyndhurst Precision

Sales Order Processing

Efficiently capture all customer data your need, easily enter orders onto the system ready for production, and control the contract review and order acknowledgment processes.

Store information from customers for processing repeat orders.

Features:

- Simple order entry

- Contract review & FAIR staged gates

- Order acknowledgement

What it means to your business

- Build your library of industry & material specs, parts & routes to allow streamlined entry of sales orders

- Ensure contract reviews are complete up-front to reduce risk to your business

- Prompt order book acknowledgements to customers improve job visibility to improve customer confidence

Production

Tricorn: Enterprise allows you to maintain comprehensive engineering details, and ensure they are visible to the right people at the right time.

Features:

- Create job cards

- Technical documentation

- Scheduling

- Machine loading

- Configuration management

What it means to your business

- Part issue & drawing issue control ensure you are always working to the latest customer specifications

- Ensure that your shop floor have access to all the required information at the relevant time, ensuring the highest quality product

“Everything is integrated now. We have the shop floor data capture and document management included, so everything is on one system. We’ve improved efficiency of production engineering processes by 40%, and have now generated new saleable capacity, without increasing our costs.”

Lyndhurst Precision

Shop Floor Data Collection

Tricorn: Enterprise’s touchscreens allow operators easy access to all relevant information, ensure accurate job costings to inform pricing, and provide comprehensive WIP tracking.

It not only captures when operators clock on or off and scan on or off jobs, it gives them live work-to-lists and allows them to report rejects without leaving the shopfloor.

Features

- Real-time data collection

- WIP tracking

- Job costing information

What it means to your business

- Track where jobs are in the process, in real-time, with employees clocking on and off jobs and parts on the line

- Accurately measure how long a process takes, and how much it will cost the business, so you provide accurate job costing

- Employees can capture rejects, lost time & machine breakdowns through the SFDC interface, without having to leave the shop floor

- Track who did what activity, for which job, when and for how long, to provide complete audit traceability, for AS9100 & ISO9001 compliance

Human Resources

Effectively manage human resources to track time-and-attendance and monitor skills and training plans to ensure operators are trained for work they perform.

Features

- Time & attendance

- Skills Matrix

- Approved operators

What it means to your business

- Monitor time & attendance to track hours worked, and identify employees working overtime, or coming in late to make employment decisions

- Identify the key skills required for each operation and match your employees’ skill levels against requirements

- Prevent operators from carrying out operations they aren’t qualified for & identify any training needs

Reporting

There are two forms of reporting available for Tricorn: Enterprise:

- In the system itself, you can create and run reports efficiently and effectively. Schedule them to auto-run and share with senior leadership, colleagues and teams.

- Or use the cloud-based AnalytiQs app. Simply set-up KPIs to track with drag-and-drop functionality; personalise dashboards for each user; and watch as they update in real-time, providing information to the shopfloor, the boardroom, or your mobile phone.

Features:

- Auto-generate reports

- Report scheduling

- Share reports

- Produce bar charts, pie charts and line-graphs

What it means to your business

- Streamline reporting by setting up KPIs and key reports that schedule to run at designated dates & times

- Increase company transparency and collaboration by sharing reports via email with your colleagues and teams

Tricorn: Enterprise Customers

|

A growing company specialising in precision laser cutting, FC Laser faced a number of challenges that many manufacturing companies can relate to. With DNAsme FC Laser has allowed for better control over business performance and ensured the best use of resources in order to significantly reduce the time required for job processing.

|

Since 1986, Lyndhurst Precision Engineering have been working to supply the demand for tooling and engineering equipment in the nuclear, aerospace, medical and defence sectors. With highly complex jobs, a standard production control solution would not satisfy their needs. With DNAsme however, production engineering processes have become 40% more efficient.

|

Request A Free Demo

|

|

|

Fusion Hive,

North Shore Road, Stockton-on-Tees, TS18 2NB Phone: 0330 236 9278 |

|